- The key drivers, restraints, & opportunities and their detailed impact analysis are explained in the study.

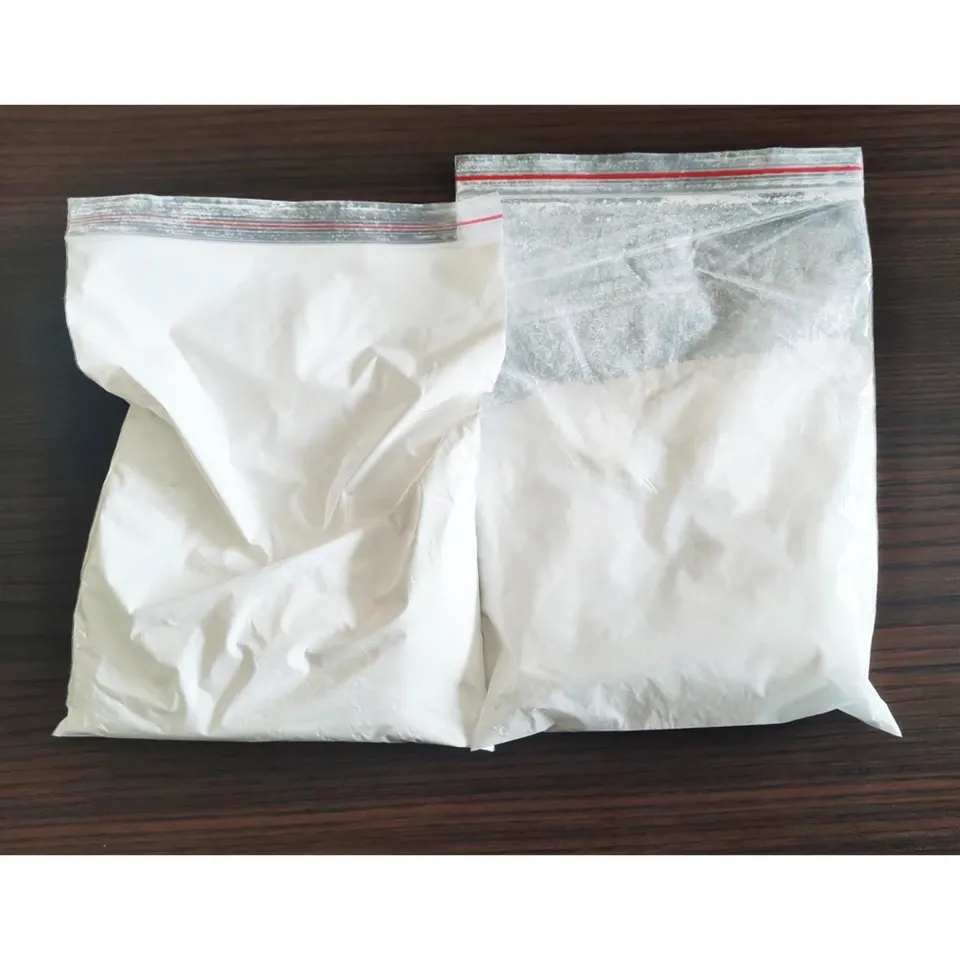

High Scattering Power TiO2 DongFang R5566

- One of the best ways to find a reliable rutile titanium dioxide supplier is to conduct thorough research and due diligence. This may involve reading customer reviews, conducting site visits, and requesting samples for testing. By taking the time to carefully evaluate potential suppliers, you can ensure that you are making an informed decision.

- Resistant

Resistance to heat, light and weathering prevents degradation of paint and in films and embrittlement of plastics.- Resistant

- NIOSH research has shown that long-term exposure to high levels of titanium dioxide dust can lead to lung fibrosis, a condition characterized by the scarring of lung tissue. As a result, NIOSH recommends employers implement engineering controls, such as local exhaust ventilation, and administrative measures, like proper personal protective equipment (PPE) and regular medical surveillance, to minimize worker exposure.

- Sunscreens are essential for protecting our skin from the harmful effects of ultraviolet (UV) radiation. Among the various ingredients used in sunscreens, titanium dioxide is a popular choice due to its effectiveness and safety. In this article, we will discuss the role of titanium dioxide in sunscreens and its benefits for skin health.

- Polymers

- Titanium dioxide anatase is a crystalline form of titanium dioxide, widely used in various industries due to its unique properties. As a supplier of titanium dioxide anatase, we understand the importance of providing high-quality products to meet the diverse needs of our customers.

- Anatase, known for its excellent photocatalytic activity, is primarily used in the production of advanced materials and environmental protection products. Its unique ability to break down pollutants under sunlight makes it an ideal choice for air purification and self-cleaning surfaces. On the other hand, Rutile, with its superior opacity and durability, is more commonly used in the coatings, plastics, and paper industries, providing a white pigment and UV protection.

- 2. Particle Size and Shape The particle size and shape of ZnS can significantly impact its performance in various applications. Therefore, it is essential to choose suppliers who can offer a range of particle sizes and shapes to suit different requirements.

- Trott, L.H. (1927). Lithopone and Its Part in Paints. The New Jersey Zinc Company..

By doing so, we achieve cost reduction, increased film strength and improved fungicidal and algaecidal properties.

- P25 Titanium Dioxide A Versatile and Essential Ingredient in Manufacturing

- Furthermore, CL 77891 is dedicated to sustainability and environmental responsibility in their operations. They adhere to strict standards and practices to minimize the environmental impact of their production processes, ensuring that their products are not only high quality but also eco-friendly. By choosing CL 77891 as your titanium dioxide supplier, you can be confident that you are supporting a company that prioritizes sustainability and ethical practices in everything they do.

- Furthermore, rutile's high refractive index and dispersion make it ideal for use in jewelry and gemstones. Although less commonly used than other gem materials, synthetic rutile can be cut and polished to exhibit a striking play of light, similar to that of diamonds. In the field of electronics, rutile titanium dioxide's semiconducting properties find application in solar cells and sensors.

pigment lithopone quotes factories. It is non-toxic and does not pose a risk to human health or the environment when used in accordance with industry guidelines. This makes it a preferred choice for manufacturers looking to create sustainable products that meet regulatory requirements for safety and environmental protection.

There are two primary forms of titanium dioxide commercially available: anatase and rutile. The rutile form is typically used in sunscreens due to its superior ability to handle UV rays and stability in the presence of UV light. The anatase form is typically used in other types of products, such as paint. Another plus of the rutile form is that its UVA protection extends past 400 nanometers, which is the upper limit of UVA.

Paint manufacturers often conduct stringent quality control tests to ensure that the anatase titanium dioxide meets the desired specifications and performance requirements Paint manufacturers often conduct stringent quality control tests to ensure that the anatase titanium dioxide meets the desired specifications and performance requirements

Paint manufacturers often conduct stringent quality control tests to ensure that the anatase titanium dioxide meets the desired specifications and performance requirements Paint manufacturers often conduct stringent quality control tests to ensure that the anatase titanium dioxide meets the desired specifications and performance requirements anatase titanium dioxide for paints factory.

anatase titanium dioxide for paints factory.Titanium is one of the most common metals on earth, but it does not occur naturally in this elemental form. TiO2, also known as titanium (IV) oxide or titania, is the naturally occurring compound created when titanium reacts with the oxygen in the air. As an oxide, titanium is found in minerals in the earth’s crust. It is also found with other elements, including calcium and iron.

Prices increased somewhat in the Asian market during the third quarter of 2021. After a steady recovery since mid-June, its price in India fell slightly in August, pushed down by lower import prices. Titanium dioxide prices continued to rise in the Chinese domestic market, with FOB Wuhu talks for Rutile grade TiO2 settling at 3125 USD/MT for the week ending September 24th.

High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product

High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product